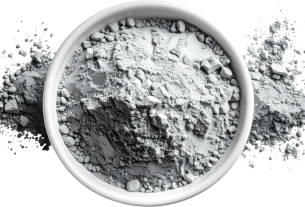

The zinc oxide manufacturing industry plays a vital role in zinc oxide processing. This industry is highly useful in various sectors, including pharmaceuticals, cosmetics, paints, rubber, and ceramics. Zinc oxide is a popular, versatile compound. It is anti-corrosion and offers good thermal stability. Furthermore, it acts as a UV protector.

Zinc Oxide Manufacturing in Life

Zinc oxide is produced using three methods, each with its own unique characteristics. These methods include direct, indirect, and wet chemical methods. Each has its own advantages.

Zinc oxide will continue to develop with the support of technology, making it a crucial material for today’s chemical industry. Let’s learn more about zinc oxide.

The Role of Zinc Oxide in Various Industries

Zinc oxide is widely used as an additive or primary ingredient in products. Its success, of course, depends on the quality of zinc oxide manufacturing, particularly particle size, purity, and consistency.

In cosmetics, zinc oxide is used as a base for sunscreen products. Skin prone to acne, oily skin, and redness can benefit from this product. This product will provide protection from sun exposure.

Zinc Oxide Production Process

Zinc oxide is generally produced through three methods. More details are as follows:

- Direct method: This process involves the direct oxidation of the metal. In this process, zinc metal is vaporized and oxidized.

- Indirect Method: Pure zinc metal is evaporated at high temperatures and then oxidized. This process produces high-purity ZnO.

- Wet Chemical Method: This process involves a chemical reaction. Zinc sulfate is reacted with alkali to form zinc oxide, which is then dried and calcined.

Zinc Oxide Applications in Various Industries

The applications of zinc oxide manufacturing are extensive, particularly for the rubber and cosmetics industries. In the rubber industry this is very important because as a vulcanizer, elasticity is increased and durability is better.

For the pharmaceutical and cosmetic industries, zinc oxide is the main ingredient in sunscreens, medicated powders, and ointments. It’s known for its ability to protect against ultraviolet rays and accelerate the healing process.

There’s also another application for the paint and coating industry. This material is highly corrosion-resistant, making it highly useful for automotive and industrial applications. In addition to its use in the aforementioned industries, zinc oxide is also widely used in ceramics. It is used as an additive in glazes. It enhances the aesthetics due to its luster. Furthermore, it also increases the ceramic’s durability at extreme temperatures.

In conclusion, the role of zinc oxide manufacturing continues to expand. As its usefulness, this technology will continue to be used in various industries. This will support industrial growth in facing future market competition.