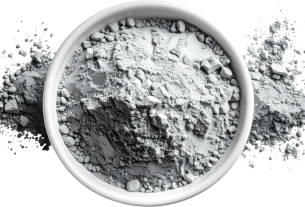

A simple white powder called zinc oxide quietly helps many everyday items work better. This handy zinc oxide raw material strengthens car tires, adds protection in electronics and provides gentle comfort to skin creams. Its special abilities make it an important ingredient for industrial products that want to create safe, strong, and reliable products.

Why the Grade of Zinc Oxide Raw Material Dictates Final Quality?

The quality of zinc oxide changes everything. A batch with 99.9% purity has extremely tiny amounts of unwanted metals. Meanwhile, a lower-grade batch can carry more harmful elements like cadmium.

Even a small difference can affect how rubber cures and how long tires last. Factories that use zinc oxide made from high-grade metal have an easier time meeting strict global standards without extra work.

- Helps Factories Make Reliable Products

Products turn out the same every time, only when the zinc oxide used in them stays consistent. The shape and surface area of the powder decide how the rubber thickens and hardens. Some production methods create consistent results, while others produce wide changes from batch to batch.

Rubber factories often run on tight schedules, so even a small shift in zinc oxide quality can change curing time and strength. Using a stable and trusted batch keeps the process smooth and reduces waste.

- Improves Gloss, Color, and Tile Strength

Ceramic tiles also depend on zinc oxide. Adding a small amount can stop cracks on tiles fired at high temperatures. It also affects shine and color. But if the zinc oxide carries unwanted minerals, the glaze can bubble or create tiny holes. Switching to a higher-purity source greatly reduces defects and keeps tiles looking clean.

- Protects Sensitive Electronic Parts

Certain electronic parts, like varistors, need zinc oxide with very low levels of salt-like elements. Even a tiny amount of sodium or potassium can change how the part handles electricity.

Suppliers who wash and heat-treat their zinc oxide carefully can keep these impurities extremely low. This helps electronic parts survive powerful electrical surges without getting damaged.

- Supports Better Paints and Coatings

When zinc oxide is milled into tiny particles, it scatters sunlight more effectively. This reduces the amount of titanium dioxide needed and helps coatings last longer under strong UV light. Small particles also release zinc ions slowly, which helps stop fungus growth on painted surfaces.

High-quality rubber, smooth ceramics, strong electrical parts, and long-lasting coatings all rely on zinc oxide raw material. Setting clear rules for purity and consistency, then sticking to a trusted supplier, helps factories run better, reduces complaints, and cuts down production costs.